技术赋能|三联机械煤矸石的制砖工艺

我国是煤炭资源的开采与利用大国,每年会产生几亿吨的煤矸石。目前我国对煤矸石的利用率还是比较低的,因此造就了大量的煤矸石对环境的破坏影响,比如说占用大量的山林让植物无法生长,下雨时矿渣里的黑碳素会随水流流到江河湖泊里污染水源,还会造成塌方等。因此,有效处理煤矸石对于环境保护和资源节约具有重要意义。

China is a major country in the extraction and utilization of coal resources, generating hundreds of millions of tons of coal gangue annually. Currently, the utilization rate of coal gangue in our country is relatively low, which leads to significant environmental damage. For instance, it occupies a large amount of forest land, preventing plant growth, and during rain, the black carbon in the mine slag can flow into rivers and lakes, polluting water sources, and it can also cause landslides. Therefore, effectively dealing with coal gangue is of great importance for environmental protection and resource conservation.

S.L

煤矸石的运用

煤矸石的再次利用方式就是道路铺设、送入水泥厂和制砖厂等,传统的制砖生产过程中,通常用烧结工艺,一方面对环境污染有影响,另一方面是砖厂的烧结温度要求较高,限制了煤矸石在这些领域的应用比例。

The reuse of coal gangue includes paving roads, sending it to cement factories, and brick factories. In traditional brick production processes, sintering technology is commonly used, which not only affects environmental pollution but also requires high sintering temperatures in brick factories, limiting the application ratio of coal gangue in these fields.

工艺创新 | Process Innovation

三联机械伺服砖机生产线,实现了煤矸石在干法制砖工艺中的应用,生产的产品包括墙砖、地砖以及大型生态挡土墙,同时也适用于轻质墙板生产线。

S.L Machinery servo brick machine production line has realized the application of coal gangue in dry process brick making, producing products including wall bricks, floor brick, and large ecological retaining walls, and is also suitable for lightweight wall panel production lines.

制砖技术的应用 |

Application of Brick Making Technology

三联机械砖机设备可通过煤矸石配比其他砂石骨料,替代天然砂石,用于生产建筑砌块,标砖等各种水泥制品,这种方式不仅有效解决了废料堆积造成的环境问题,而且相比传统制砖技术,三联机械砖机设备在降低生产成本的同时,实现了更加环保的生产过程。

S.L Machinery brick machine equipment can use coal gangue in combination with other sand and stone aggregates to replace natural sand and stone, used for producing building blocks, standard bricks, and various cement products. This method not only effectively solves the environmental problems caused by the accumulation of waste but also achieves a more environmentally friendly production process while reducing production costs compared to traditional brick making technology.

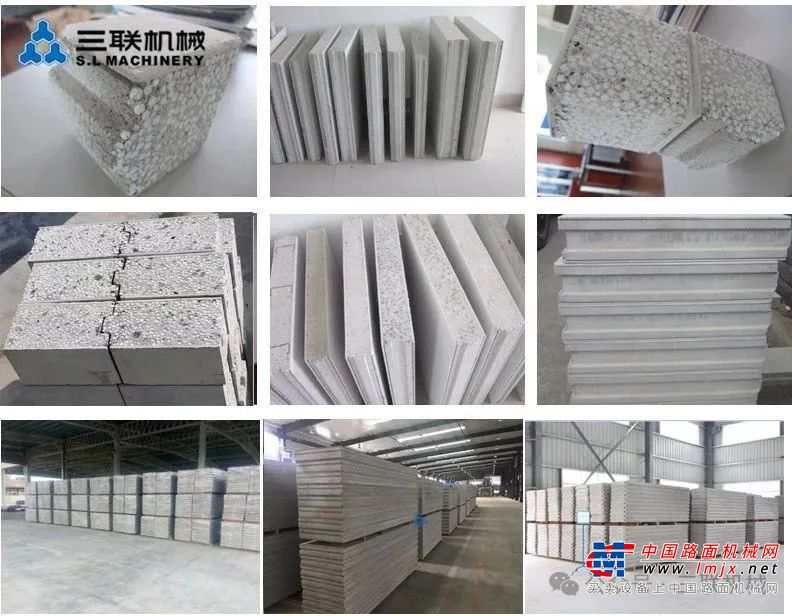

轻质墙板机上的应用 |

Application on Lightweight Wall

Panel Machine

三联机械轻质墙板机在生产轻质墙板时,主要采用工业副产品(如煤矸石、粉煤灰、矿渣)作为原料,有助于减少资料浪费,整个生产过程低噪音、低排放,契合绿色资源可持续发展目标。

S.L Machinery lightweight wall panel machine mainly uses industrial by-products (such as coal gangue, fly ash, slag) as raw materials when producing lightweight wall panels, helping to reduce material waste. The entire production process is low-noise and low-emission, aligning with the goals of green and sustainable development.

S.L

资源再造

煤矸石曾经是困扰环境的重要因素,如今,借助三联机械的干法制砖技术,无论是生产墙砖、地砖,还是生态挡土墙,三联机械的制砖工艺能让煤矸石高效利用、减少污染、降低成本,真正实现"环保+效益"双赢!

#水泥砖#

Coal gangue used to be a significant factor troubling the environment, but now, with the help of S.L Machinery dry process brick technology, whether it's producing wall bricks, floor brick, or ecological retaining walls, S.L Machinery brick making process can make efficient use of coal gangue, reduce pollution, and lower costs, truly achieving a "environmental protection + benefit" win-win situation!

新闻投稿:news@lmjx.net

相关资讯

2025专用汽车产业发展论坛成功举办,聚力重塑共赢 引领产业价值升级

11月12日,以聚力•重塑•共赢为主题的2025专用汽车产业发展论坛圆满落幕,来自全国约500名企业代表齐聚一堂,共话行业新。

以匠心致初心,以技能筑信任——第六届丰田产业车辆全国技能大赛圆满落幕

2018-2024年,7年内丰田叉车面向所有授权经销商五次举办技能大赛。我们始终相信:卓越的产品,需要同样卓越的服务来守护。

拓普康索佳闪耀第二届中国测绘地理信息技术暨北斗应用博览会,全流程数字化方案引行业瞩目

第二届中国测绘地理信息技术暨北斗应用博览会拓普康索佳全流程数字化解决方案更简单 | 更高效 | 更智能金秋时节,行业盛会再启新篇!20。

宁波如意:公司参加起草2项标准入选工信部2024年应用推广典型案例!

近日,工业和信息化部正式公布了2024年百项团体标准应用推广典型案例名单。由公司参加起草的《氢燃料电池工业车辆》 。

中国水电基础局调研上海金泰工程机械有限公司

11月12日,中国水电基础局有限公司副总经理杨振甲率华东事业部和四公司团队赴上海金泰工程机械有限公司开展深度调研考察。

中交西筑:公司开展制度宣贯专题培训

为全面推进公司内控管理体系建设,推动各项规章制度的有力有效落实,11月13日,公司召开制度宣贯月启动会暨第一次制度宣贯专题培训。

今日头条

- 第八届工程机械行业标准化工作会议在徐州成功召开

- 戴纳派克第六代SEISMIC双钢轮压路机新品发布暨经销商大会圆满落幕

- 稳居行业第一!徐工受邀参加《财富》中国500强峰会

- 聚焦绿色智慧养护|德基机械DGRE4000D安徽工地观摩获盛赞

- 备件大促今日开启!“玛”上下单,抢占优惠席位

- 同舟致远·共赢新程 泰凯英上市启航仪式在青岛隆重举行

- 2025年10月销售挖掘机18096台,同比增长7.77%

- 北京卓众出版副总经理谢艳丽一行到访开云官方入口

- 徐工XLC18000M与它的“初创玩家”:一场奔赴陕西的“破局计划”!

- 硬核装备!内蒙矿山再添“矿山巨兽”——10台小松HD785-7矿用卡车批量交付,开启高效开采新篇章!